Project description

Industry/application group:

Exterior parts for motorcycle spare parts

Result:

UV-resistant SLS printed parts for motorcycle spare parts. Fulfilling highest mechanical properties and resistant to sunlight exposure.

Spare parts production as a challenge

Motorbikes have short model cycles and are changing their design and colors according to fashion. New models are introduced almost every year. Spare parts change with them and after a several years they are often no longer fully available. In addition, customers wish a personal design and are looking for individual accessories to create a fully customized motorcycle.

UV-resistant spare parts from the 3D printer

Exterior components for motorcycles are parts that have to withstand harsh environmental conditions such as:

- Humidity

- Dirt

- Temperature cycles (minus and plus)

- Sunlight exposure

- Higher mechanical requirements as high stiffness

- Cleaning agents

For conventional materials in SLS 3D printing, it is a challenge to realize quickly available spare parts that can resist these hard conditions.

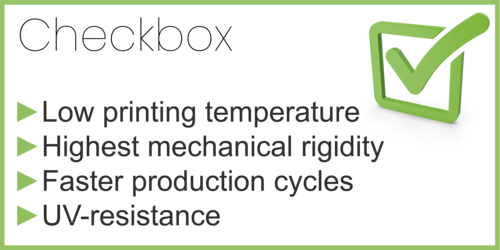

Checked and tested: TIGITAL® 3D-Set TPP 371/80005

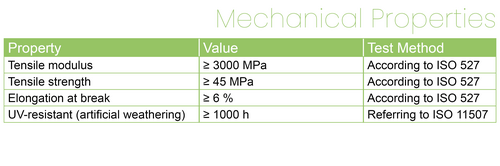

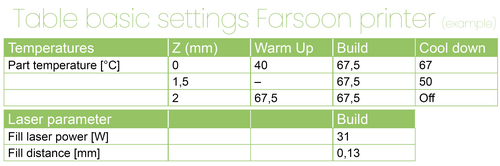

With completely new, duroplastic-based materials for SLS 3D printing, TIGITAL® 3D-Set has developed an innovative material class that has been specially tailored to the quality requirements of motorcycle manufactures.

TIGITAL® 3D-Set TPP 371/80005 fully complies with UV standards for exterior conditions as artificial weathering cycles including humidity, salt spray and temperature cycles with a nearly unchanged mechanical property profile before and after test.

Approval and additive manufacturing

After the final component approval, the OEM has several options for the additively manufactured spare part:

- An approved spare parts partner prints the desired object

- The OEM commissions a 3D printing service partner for additive manufacturing

- The OEM manufactures prints the spare parts with its own SLS 3D printer

Coated, printed and delivered

3D printed components can be powder coated with TIGER Drylac® and printed with TIGITAL® Inks. This allows both the optical properties and the service life of the printed object to be specifically improved.

“TIGITAL® 3D-Set PPP 371/80005 represents an innovation in the field of UV-resistant SLS materials based on duroplastics. This allows me to produce spare parts with high mechanical stiffness, which are exposed to the harsh conditions of the motorcycle environment – UV exposure, as well as exposure to various chemicals.”

INFORMATION TO THE USER - DISCLAIMER

TIGER’s verbal and written recommendations for the processing, use and application of our products, including the information, product properties (e.g. mechanical properties and emission properties) and processing parameters (e.g. laser power, part bed temperatures, post-curing conditions) provided in this use case, are based upon our experience and in accordance with present technological standards. These are given only in order to support the user, are noncommittal and do not constitute any additional commitment or product specification. The user shall be solely responsible for checking and verifying the suitability and/or fitness of our products and exemplary processing conditions for the intended use, application and process. Further, the user shall be solely responsible for the appropriate, safe and legally compliant use, processing, handling and application of our products as well as for any related 3D printed parts. To the extent permitted by applicable law, TIGER, its employees, boards, OWNERS, agents, subcontractors or affiliates can NOT be made liable for any damages, whether caused directly or indirectly BY or being related to this use case, or for any related loss of profit, loss of goodwill, or any other consequential damages.

Back to overview